Optimising your warehouse operations with a proactive approach involves collaborating with your team to identify areas of improvement through key warehouse figures such as open warehouse tasks, processing times, and resource utilisation. Using a range of analytics, you develop and implement solutions that align with your business needs and help your staff perform at peak efficiency.

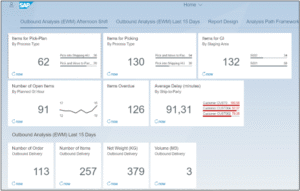

- Real-time visibility into critical metrics such as inventory accuracy, stock turnover, and resource allocation. Advanced dashboards enable you to monitoring. Here are some key figures from SAP,

- Inventory Accuracy: Directly compares physical and system inventory for variance control. SAP customers often achieve 98–99% accuracy rates.

- Picking Accuracy: Tracks the percentage of orders picked without error. After migrating to SAP S/4HANA, businesses have improved picking accuracy from 92% up to 99%.

- Labor Productivity: Measured in orders processed per hour or per employee; with SAP tools, companies have achieved labor productivity increases of 15–18%.

- Order Fulfillment Cycle Time: Time from order placement to shipment. Benchmark cycle times using SAP analytics to pinpoint and address process bottlenecks.

- Open Warehouse Tasks: Monitoring open vs. completed tasks in SAP EWM allows for dynamic resource allocation and fast bottleneck detection.

- Dock-to-Stock Cycle Time: SAP-tracked time for goods from arrival at the dock to storage. Efficient SAP users drive this metric down to under 2 hours for key products.

Customer satisfaction and inventory management are enhanced through real-time stock visibility. Automatically tracking stock quantities, stock age, and stock locations across all storage bins, supporting strategies such as FIFO/FEFO. Stock integrity is ensured via cycle counting and (low tolerance and empty bin checks), automated variance reporting, minimising discrepancies they by achieving a stock accuracy typically above 98%.

Reduce manual handling, errors, and costs via streamlined inbound processes such as system-directed put away, barcode scanning, and in some deployments, automated retrieval. SAP supports tracking inbound/outbound delivery creation, advanced shipping notifications, and provides KPIs like receiving efficiency and put away cycle time.

Identify the best-fit solutions for your warehouse by working with the staff, utilising data and leveraging SAP’s analytics to map out key improvements and future requirements. With SAP, you can track and optimize:

- Resource Utilization: Measure and plan staff or equipment based on usage load and identify over/under-employed areas.

- Task Grouping: Assign tasks to specific resources or activity areas/pick zones, reducing travel time and boosting productivity—potentially increasing order fulfillment rates by 10–20%.

- Inventory Turnover: SAP records can be used for continuous benchmarking, with high-performance operations seeing turnover rates above 8–10 times per year, depending on industry.

We provide tailored supply chain solutions built on SAP S/4HANA and SAP EWM, equipping your business with the tools to grow and drive efficiency. We deliver a true end-to-end solution customized to your business, whilst providing training and ongoing support. With SAP’s integrated training tools, ongoing support, and deep-dive reporting. Improve your processes and reduce costs by harnessing:

- Real-time analytics and alerts for underperforming KPIs.

- Standard automation for inbound/outbound processing, reducing cycle times and handling costs.

- Advanced support for bin management, task prioritization, and labor allocation.

With improved warehouse management solutions, your business benefits from streamlined processes, measurable efficiency improvements, and reduced operational costs achieving world-class benchmarks in warehouse performance and supporting long-term company growth.

Key SAP Figures and Typical Ranges

| KPI | SAP Benchmark/Range |

| Inventory Accuracy | 98–99% |

| Order/Picking Accuracy | 98–99% |

| Labor Productivity | Up to +18% post-SAP implementation |

| Dock-to-Stock Cycle Time | Less than 2 hours (best-in-class) |

| Order Cycle Time | Days to < 24 hours (target, e.g. e-commerce) |

| Inbound/Put away Cycle Time | < 60 minutes (high performers) |

| Open Warehouse Tasks | Real-time SAP tracking |

| Resource Utilization | Optimized via SAP, industry-specific |

Reached out to us to understand how we can help achieve optimisations.